Main features:

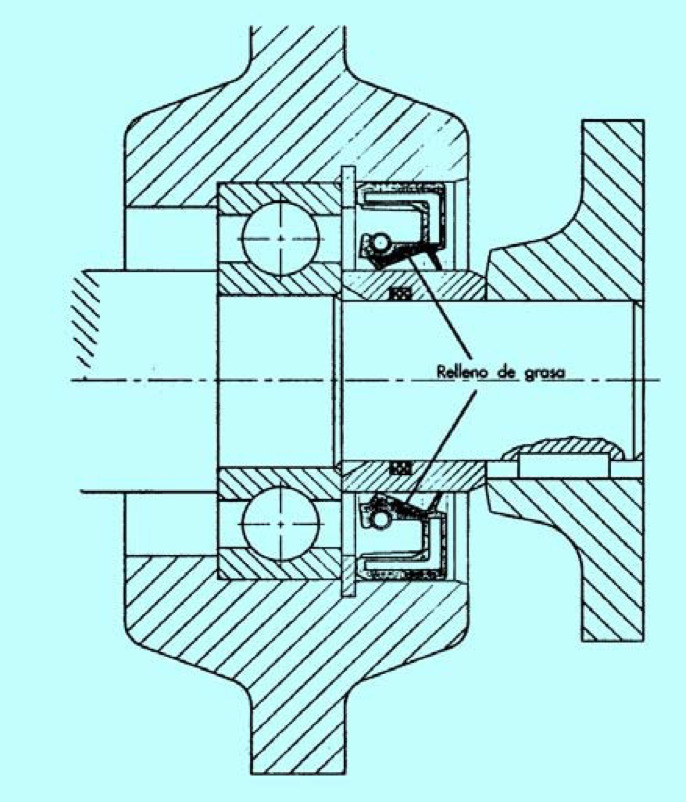

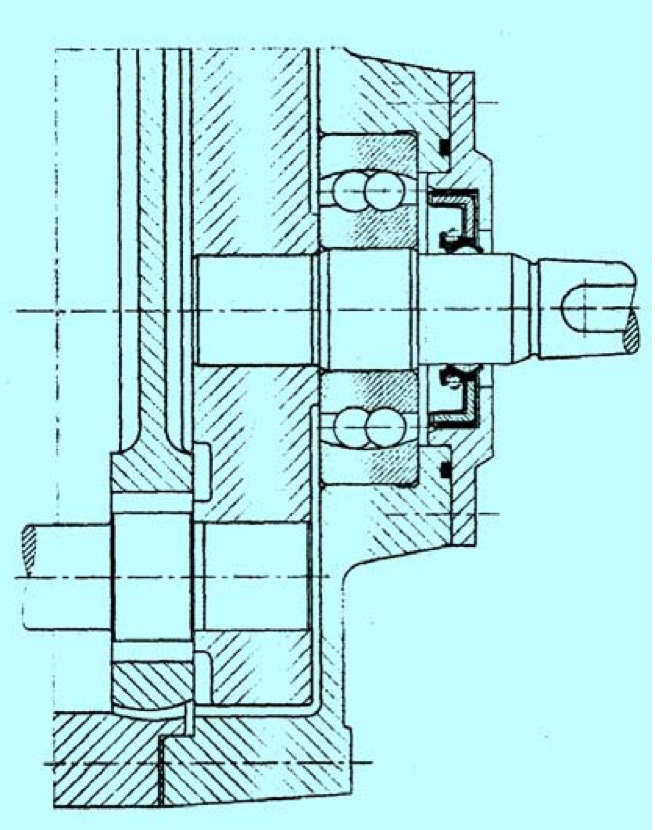

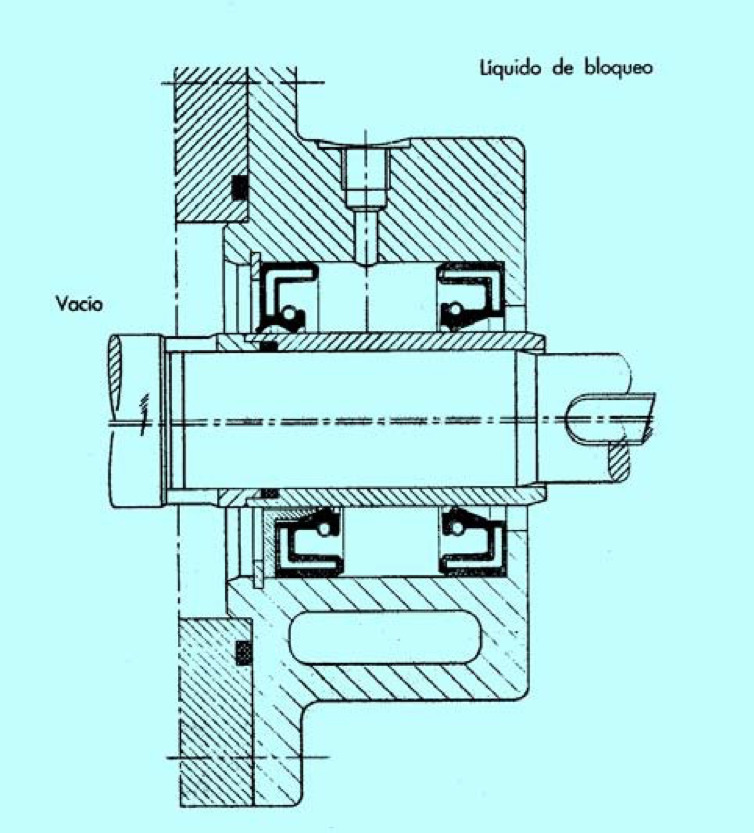

- Metal outer ring coated or uncoated elastomer.

- Sealing lip equipped with a tension spring. Its function is to guarantee the dynamic and static sealing of the axis, that is, both the axis when rotating and at rest.

- Additional lip for applications where greater security against dust and/or dirt from the outside is required.

- Manufacture according to DIN 3760, other models to be consulted.

Related documents

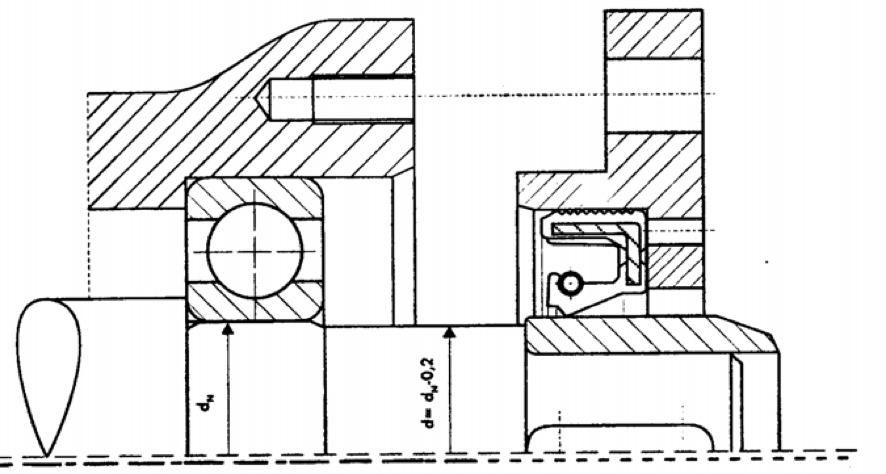

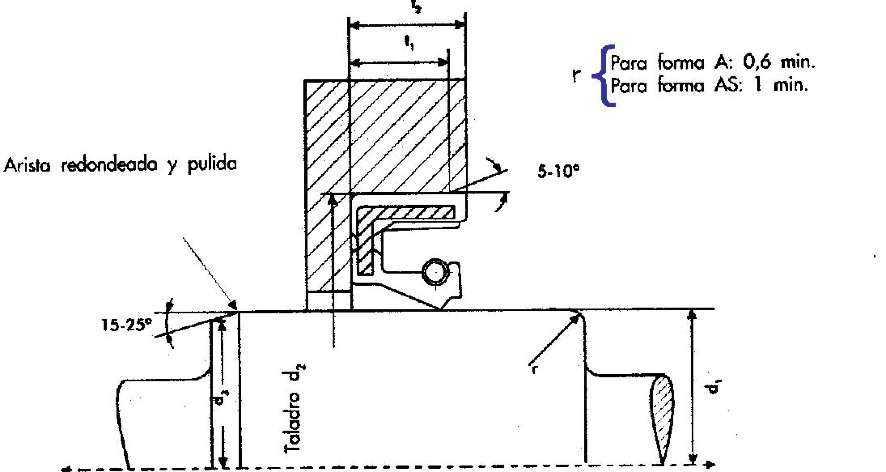

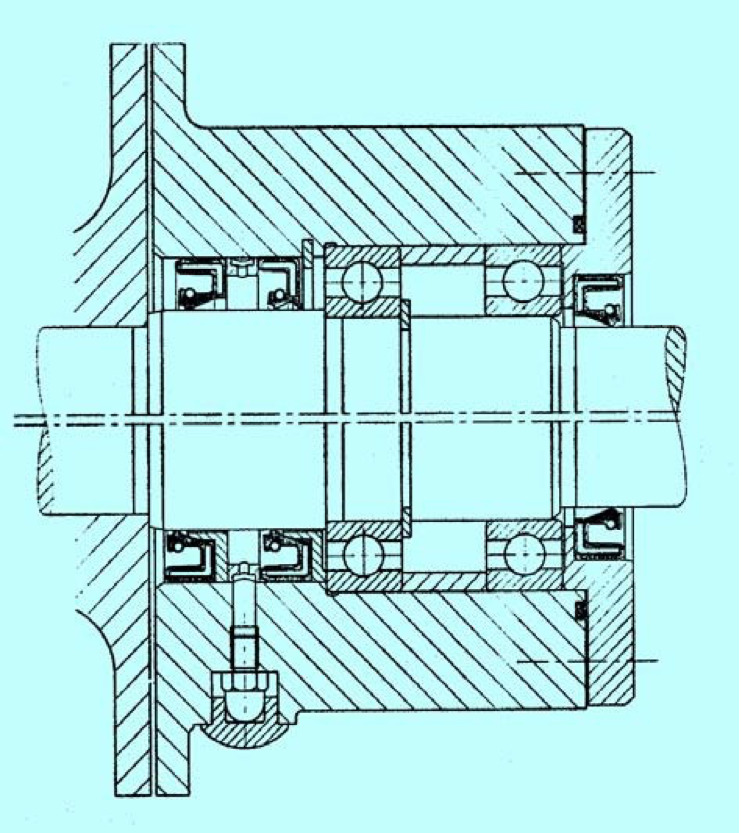

Assembly of radial seals

The allowances indicated by the manufacturer must be strictly observed:

- Material qualities and the axis' machining with Rmax = 6.3 μ.

- Tolerances of h11 for the axis and H8 for the housing.

- Shaft hardness from 45 to 60 HRc.

- Concentricity of the axis from 0.3 to 0.1 mm, according to the rotation speed.

- Dynamic eccentricity between 0.4 and 0.1 mm, according to the speed.

- Rmax housing roughness = 10-25 μ depending on the type of seal.

- The use of mounting caps may be required to avoid damaging the retainer:

- It is necessary to use chamfers or rounding radii for the assembly according to the assembly's direction.

- The diameter of the chamfer (d3) is 80% to 95% of the shaft's diameter, and according to its value (between 6 and 500mm)

Reviews

There are no reviews yet.